Mechanism: A simple mechanism composed of only a cam divider and a turret, providing various types of intermittent motion required.

Transmission: The mechanism moves in a stop-index-stop manner, and can be positioned without any locking element when stopped.

Motion: Due to the precise design of the mechanism, the transmission runs smoothly without vibration and noise.

Division: The division accuracy of the divider depends on the precise coordination of each part, the basic accuracy is ±30 seconds, and higher division accuracy can be achieved if there are special requirements.

Performance: The special design of the cam curve makes the splitter reduce the impact between the cam and the roller when running at high speed.

Curve: Provide the required curves according to different applications: 1. Deformed trapezoidal curve 2. Deformed sinusoidal curve 3. Deformed constant velocity curve.

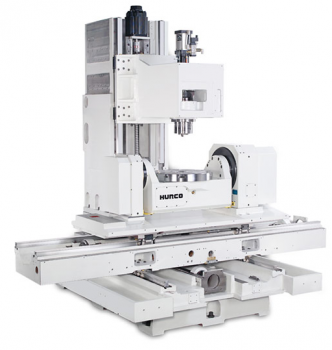

Cam divider

The use, maintenance, inspection and repair of the cam divider:

1. Before use, the oil filling bolt should be loosened to ensure the internal and external air pressure of the box balance.

2. To clean up the sundries and scraps around the transmission structure at any time. to prevent jamming of the divider.

3. The transmission parts connecting the lower input and output shafts should be regularly inspected. To prevent the coupling, pulley, sprocket, gear and output transmission body from being too loose, the tension of the belt and chain, the tooth gap of the gear, etc. should be absolutely normal.

4. If the following conditions are found, the operation should be stopped immediately. (1), abnormal vibration occurs.

(2) An abnormal sound occurs.

(3), there is a reverse impact in the static area of the cam.

(4), in the corresponding intermittent times, there is no divided output, or the divided output is unstable at a certain position, or there is no divided output at all. In the above cases, you can remove the splitter, open the back cover of the splitter, and find the reason.

A: The cam is damaged, and the cam should be replaced.

B: The needle roller bearing is damaged, and the needle roller bearing should be replaced. There are two methods: one is to loosen the output end, take out the output shaft, do not loosen the gland at the rear end, so that the axial position remains unchanged when re-installing. The second is to loosen the lock nut at the rear end of the output shaft and the output sleeve at the front end to take out the output shaft together with the sleeve. When re-installing, only the lock nut is required to make the output shaft return to its original position. Sometimes the child controls in the layout cannot be fully displayed, or we want a child control to temporarily occupy more display space. At this time, we need to use another layout management - splitter.